#Mas epoxy table top chemical resistance crack

MMA CONCRETE CRACK HEALER AND SEALER Product #684LV is a reactive methacrylate resin, which hardens rapidly with the addition of Product #695 MMA HARDENER, even at low temperatures. MMA CONCRETE CRACK HEALER and SEALER Product #684LV is typically used on bridge decks, parking structures, concrete floors or as a general penetrating sealer to prevent moisture intrusion. MMA CONCRETE CRACK HEALER and SEALER Product #684LV is a 100% reactive ultra-low viscosity methyl methacrylate resin used as a penetrating crack sealer or to fortify extremely porous concrete substrates. Repair Cracks in Bridge Decks And Similar Horizontal Concrete Surfaces Low Viscosity Fast Setting Methyl Methacrylate (MMA) Permanent Crack Repair System Links that will make your Chip Flooring installation better and easier: You can still see the ceiling lights reflecting off the surface. Here is the picture of the chip floor – that that was about 15 years old when the picture was take. Product #442 – Shinny duel component UV resistant Water Based Urethane.Product #441- Matt duel component UV resistant Water Based Urethane.It may be desirable to add an ultra violet (UV) Resistant top coating for the systems above. Product #633 – a work-horse 100% Solids Novolac Epoxy Coating – Best chemical resistance, not as good UV stability as 630.įor jobs that will see direct sunlight.Product #630 – 100% Solids Novolac Epoxy Coating – Almost the best chemical resistance, but with good UV stability.Product #2 a 100% Solids Chemical Resistant Epoxy Coating – more Chemical Resistance.Product #1 a 100% Solids General All Purpose Epoxy Coating with Good Chemical Resistance.All of the coatings in this section are highly durable and resist the abrasion of traffic. All of these products are 100% solid, zero voc. Please See Chemical Resistance Chart for a comparison of chemical resistance of the products below. The biggest difference between these coatings is the chemical resistance. There are a number of options for doing this but here are a few of the most common ones.

#Mas epoxy table top chemical resistance install

In many cases you will want to install a coating over the concrete slab. The Product #12 Primer Sealer can also be mixed with silica sand and used as a patching material for potholes and otherwise damaged concrete if required. Our optional translucent Synthetic Anti-Skid Fine may be added to the #12 if it is used in additional coats as a clear sealer. You can apply an additional coat or coats of the #12 or go on to Coating the Concrete Slab below. This is where there is a couple of ways to go. The next step is to prime the concrete with Product #12 Chemical Resistant Primer / Sealer. Sealing the Surface of the Concrete Slab. If there is going to be a chemical exposure to the surface there will it will stop the chemicals from attacking your concrete and further contaminating the soils below it. This is a highly chemical resistant joint filler.

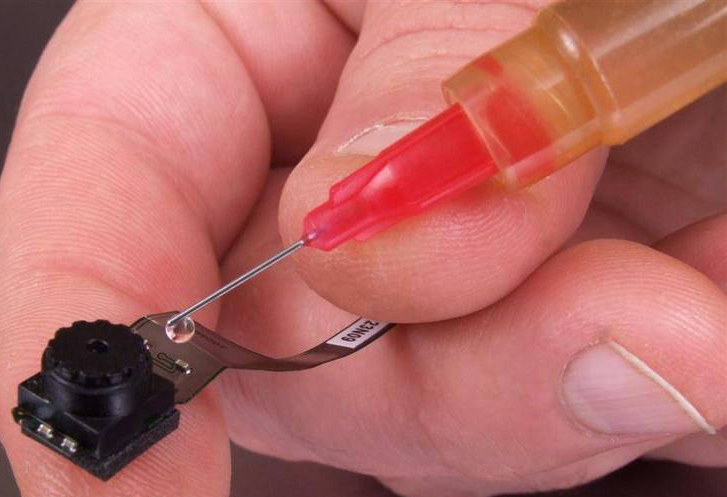

To seal these joints use Product #632 – Chemical Resistant Joint Filler. Expansion JointsĮxpansion joints are the also a very direct route for vapors to come in. In other words structurally you have the monolithic structure that the concrete was intended to be. It welds the cracks back together with a bond strength that is greater than the tensile strength of the concrete. That makes it easy to gravity feed into small cracks small porous areas of the concrete. The #684LV has about the viscosity (thickness) of diesel fuel. That is a very easy fix Product #684LV – Methyl Methacrylate Crack Healer and Sealer. Cracks are the path of least resistance, so most of your vapors come through cracks in the floor. The most direct way for soil contamination gasses to get in is through cracks. The tools below make the solution less evasive. Without the right tools these vapors in the air from contamination under that slab can be quite pervasive.Įach job needs to be evaluated on an individual bases. The following steps can be used to mitigate chemical vapors into your space above it. Stopping the migration of the gas through a slab is frequently a requirement of repurposing a space. BackgroundĬhemical contamination vapors tend to pass though a concrete slab and get into the air above. How do I stop chemicals gas vapors from contaminated soils passing though a concrete slab? This is a question I get frequently from owners and environmental mitigation experts.

0 kommentar(er)

0 kommentar(er)